Testing & Traceability

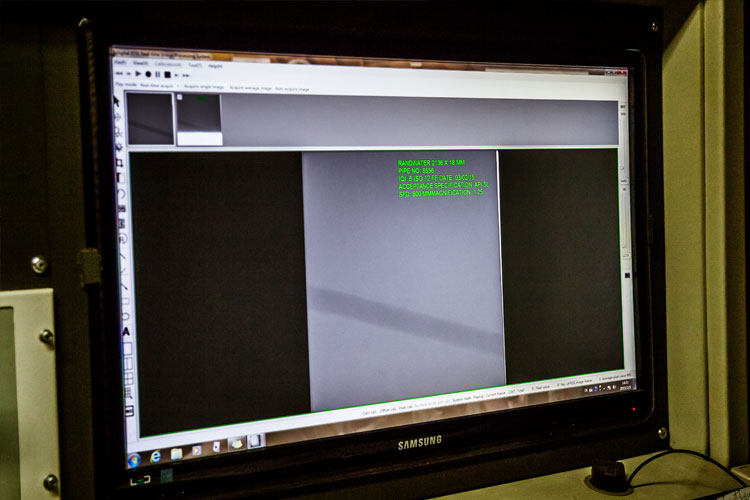

Africa pipe industries have designed and developed an electronic pipe information management system which is a real-time system used for pipe traceability and data collection.

The representatives of each manufacturing station in the factory captures the information as and when the pipes are received. This information can be incorporated into automatically generated reports to keep customers updated on the progress of the project.

The system includes safety measures, such as pipes first having to be released by the previous stations to confirm pipe quality compliances that are overseen by the quality manager. The system also records all information from the point of receiving raw materials to the final dispatch, offering the end-user reliable information.

Quality Systems

The Quality System operated by Africa Pipe Industries places emphasis on problem prevention rather than detection. The Africa Pipe Industries Quality system operates in accordance to ISO 9001:2015, by use of the Quality Manual and the Quality Plan, ITP, procedures and instructions and surveillance and audit of the various activities from the receipt of materials to final shipment of the completed product.

The day to day operation of the system is undertaken by the QA/QC Manager who shall Endeavour to continually improve the effectiveness of the system.

To ensure that all elements are controlled, Africa Pipe Industries’ produces an Inspection and Test Plan. This document controls all the various elements and indicates the procedure required and the verifying evidence required to substantiate compliance

Africa pipe industries is accredited by the american petroleum institute.